Leave Your Message

In the realm of industrial automation and fluid control systems, the efficiency and reliability of operations heavily depend on the quality of components utilized, particularly Solenoid Directional Control Valves. According to a recent report by MarketsandMarkets, the global solenoid valve market is expected to reach $6.4 billion by 2026, indicating a growing demand for these critical components across various sectors, including manufacturing, automotive, and pharmaceuticals.

The integration of advanced technologies in solenoid directional control valves not only enhances operational effectiveness but also promotes energy conservation, aligning with industry trends toward sustainability. As global procurement becomes increasingly complex, identifying the best solenoid directional control valves is essential for organizations aiming to optimize their workflows and mitigate risks. This blog will explore the solutions available to improve efficiency and reliability in fluid control applications, paving the way for smarter and more productive operations worldwide.

The integration of advanced technologies in solenoid directional control valves not only enhances operational effectiveness but also promotes energy conservation, aligning with industry trends toward sustainability. As global procurement becomes increasingly complex, identifying the best solenoid directional control valves is essential for organizations aiming to optimize their workflows and mitigate risks. This blog will explore the solutions available to improve efficiency and reliability in fluid control applications, paving the way for smarter and more productive operations worldwide.

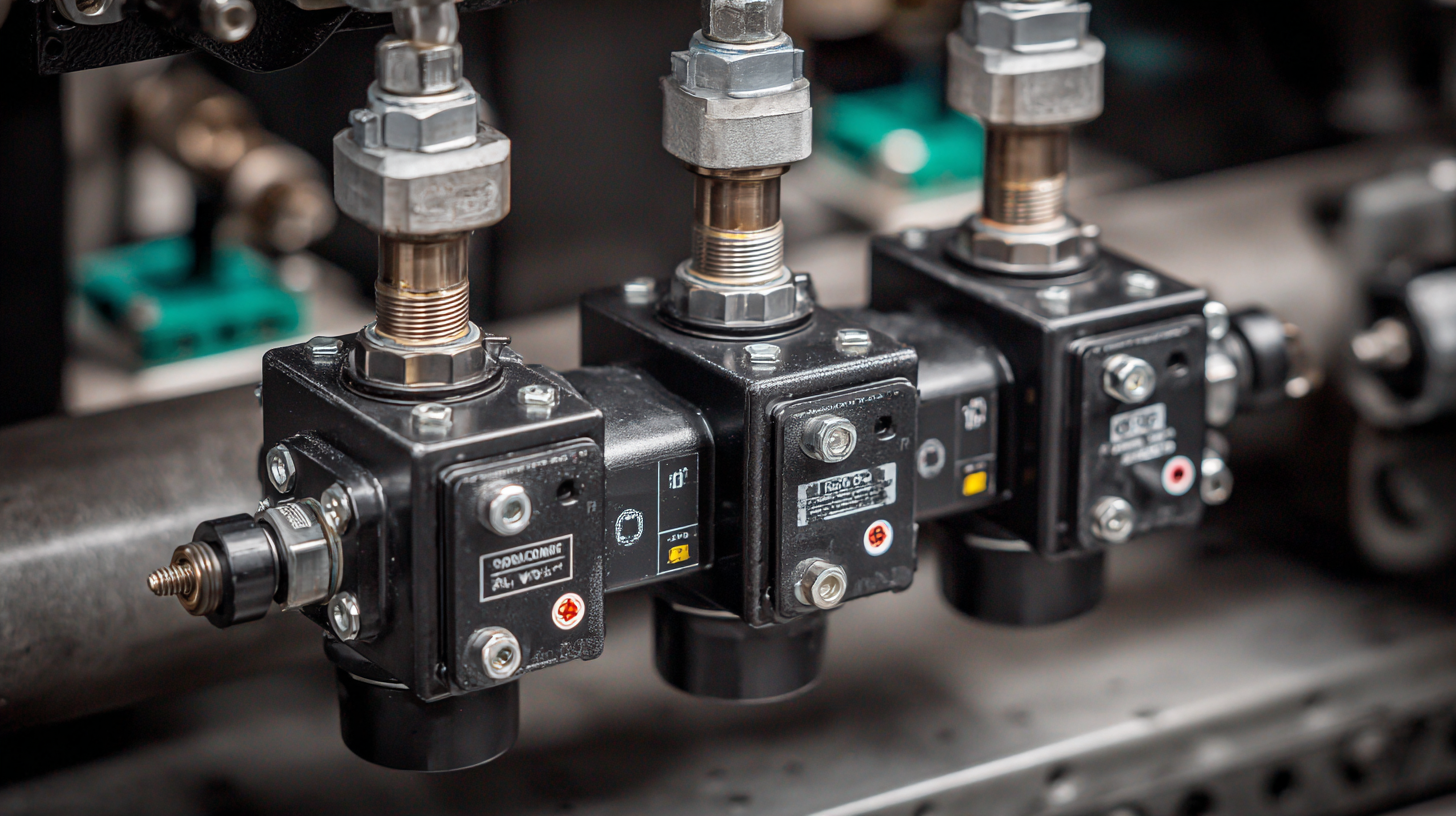

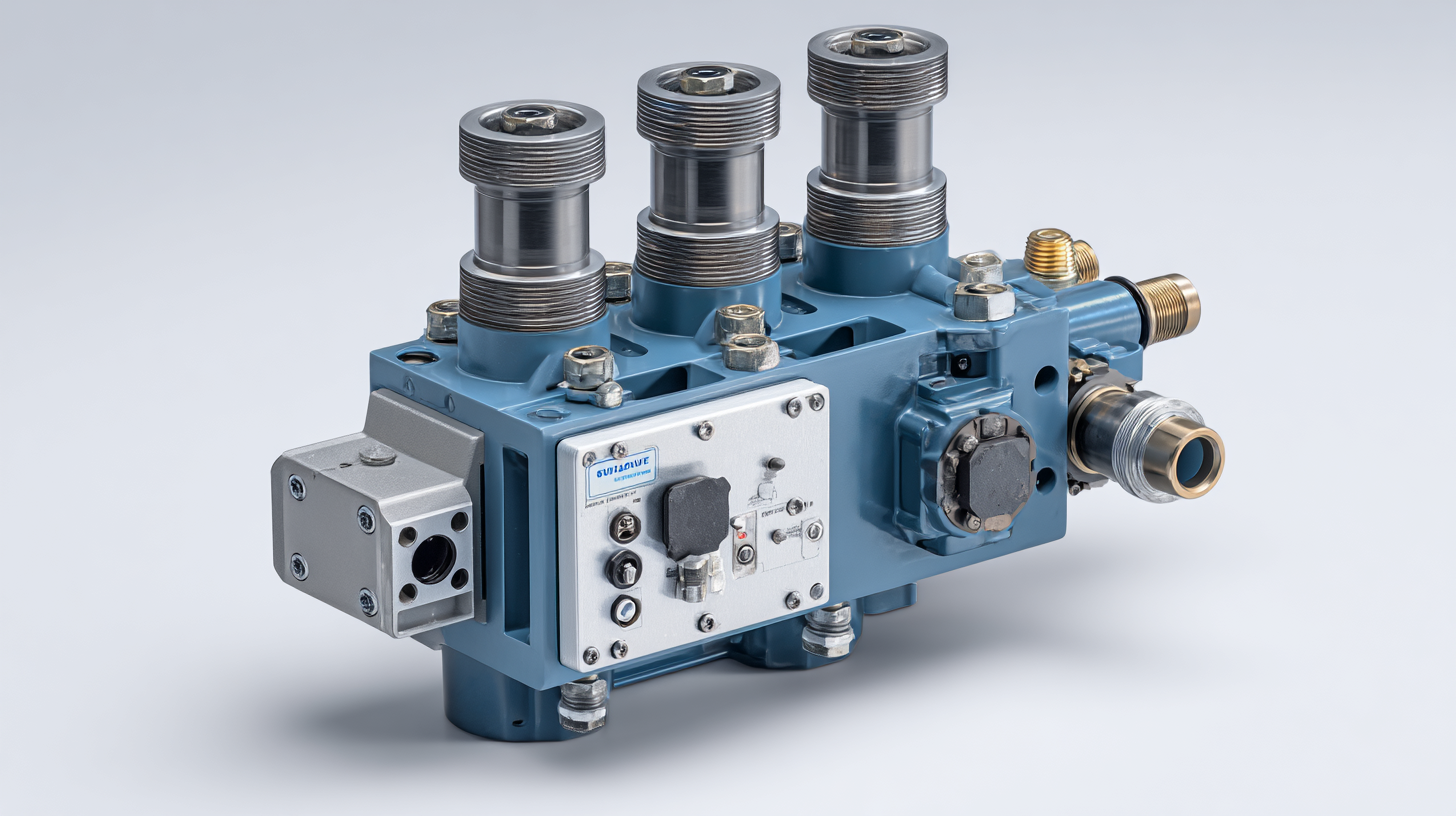

Solenoid directional control valves play a vital role in various industrial applications by regulating the flow of fluids within hydraulic and pneumatic systems. These valves provide precise control, which is essential for maintaining efficiency and reliability in processes ranging from manufacturing to automotive systems. According to a recent report from MarketsandMarkets, the global solenoid valve market is projected to grow from USD 2.23 billion in 2020 to USD 3.76 billion by 2025, reflecting an annual growth rate of 10.5%. This growth indicates the increasing adoption of these valves in industrial automation and the need for more effective fluid management solutions.

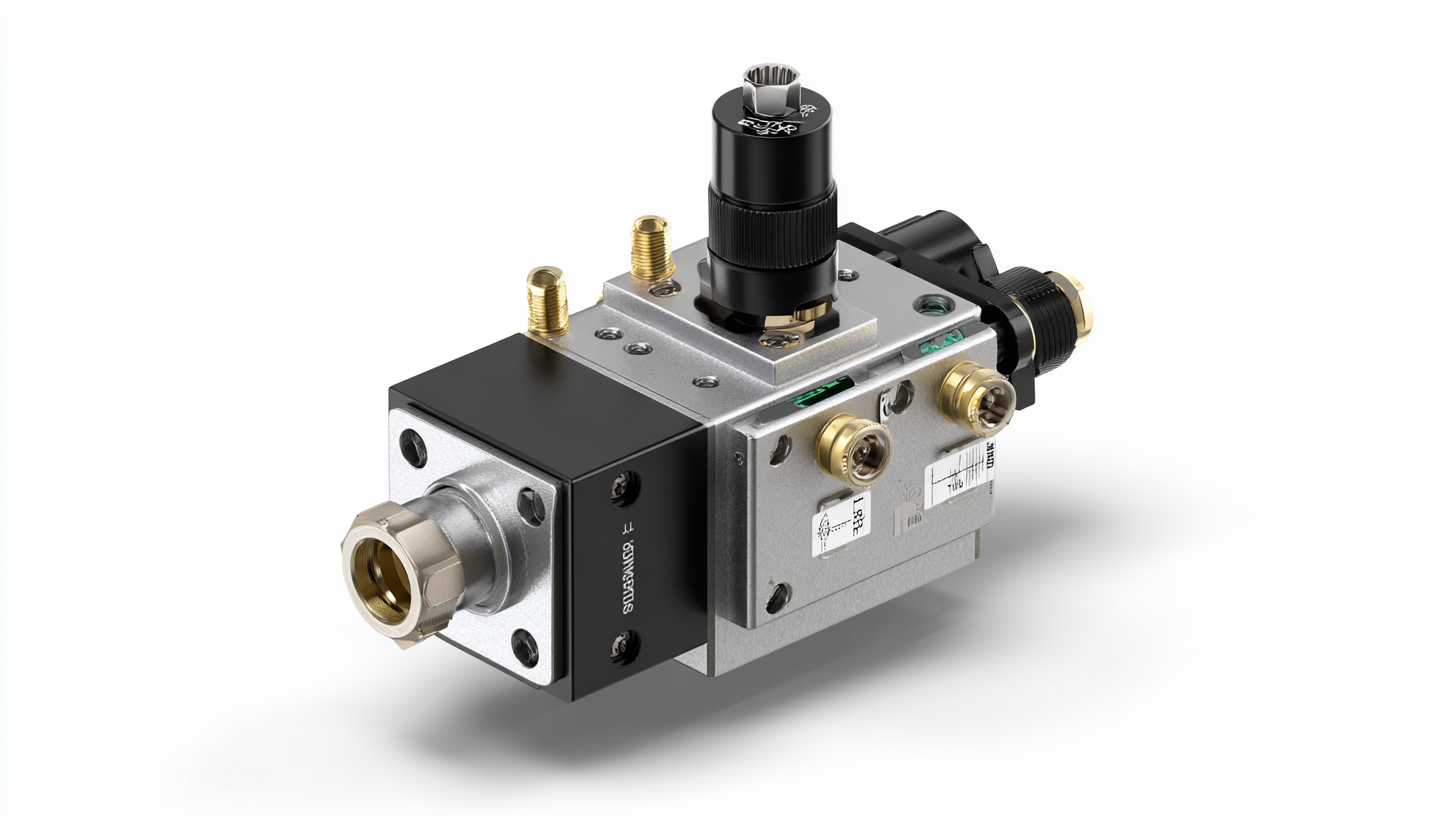

Key features of solenoid directional control valves include their compact design, rapid response time, and easy integration into existing systems. They are designed to operate with minimal noise and energy consumption while ensuring high reliability and low maintenance requirements. Additionally, the versatility of these valves allows them to handle various media, such as air, water, and hydraulic oils, making them suitable for a wide range of applications. As the industry shifts towards smart automation, the integration of solenoid valves with IoT technology is expected to further enhance their operational capabilities, positioning them as essential components in modern manufacturing processes.

As industries worldwide continue to evolve, the demand for advanced solenoid control technologies has seen a significant uptick. Recent market analyses indicate that the global solenoid valve market is projected to reach approximately $7 billion by 2027, growing at a CAGR of 5.6% from 2020. This growth is driven not only by the rapid expansion of sectors such as automation and robotics but also by the increasing need for precise control in fluid systems across various applications. The surge in manufacturing capabilities and the push for streamlined operations have led companies to seek out more sophisticated solutions, thereby elevating the role of solenoid directional control valves in procurement strategies.

Moreover, technological advancements such as IoT integration and smart manufacturing are shaping industry expectations. According to a report by MarketsandMarkets, the adoption of IoT in industrial applications is anticipated to grow at a staggering rate, resulting in more intelligent solenoid control systems that can diagnose issues and provide real-time feedback. This evolution necessitates not only reliable products but also a shift in procurement policies, advocating for suppliers who can provide high-quality, innovative solutions that ensure efficiency and reliability. As businesses prioritize sustainability and operational excellence, the strategic sourcing of these advanced solenoid technologies will become imperative in maintaining competitive advantage.

This chart illustrates the global demand for solenoid directional control valves in 2023 across different regions. The numbers represent the estimated market demand in units, highlighting significant growth areas particularly in Asia and Europe.

In the competitive landscape of global procurement, the efficiency and reliability of

solenoid directional control valves are paramount. According to a recent report by

MarketsandMarkets, the solenoid valve market is expected to grow from

$4.3 billion in 2022 to $6.1 billion by 2027, driven by increasing automation across industries.

This growth underlines the need for manufacturers to evaluate performance metrics meticulously, focusing on parameters such as response time, power consumption, and operational lifespan.

States like California have reported that the efficiency of solenoid valves can influence energy consumption by up to 20%, making it essential to select valves that minimize energy waste.

When choosing solenoid directional control valves, look for specifications that highlight reliability. The

International Electrotechnical Commission (IEC) assesses

reliability through the mean time between failures (MTBF), suggesting an MTBF of at least 15,000 hours

is standard for quality valves. Additionally, valves constructed from high-grade materials, such as brass and stainless steel, exhibit a robust performance that withstands demanding environments, significantly reducing maintenance costs.

Tips: Regularly monitor your solenoid valves’ pressure and response time to identify any anomalies early.

Always ensure that the specifications match your operational requirements to achieve optimal efficiency.

Consider integrating smart technology to monitor valve performance continuously, enhancing decision-making in procurement processes.

Cost efficiency is a critical factor in global procurement, especially when sourcing solenoid directional control valves. According to a report by Markets and Markets, the global solenoid valve market is projected to grow from $3.55 billion in 2020 to $5.89 billion by 2025, at a CAGR of 10.5%. Such growth underscores the importance of selecting quality valves that not only meet operational standards but also enhance budget management. Low-cost options may appear attractive initially, but they often result in higher maintenance costs and increased downtime, which ultimately disrupt procurement budgets.

When assessing solenoid valve suppliers, consider implementing a total cost of ownership (TCO) analysis. This approach examines not just the purchase price, but also factors in installation, operation, and maintenance costs over the product’s lifecycle. According to a study from the American Society of Mechanical Engineers, quality solenoid valves can decrease downtime by up to 40%, leading to significant savings in operational costs for businesses.

Tip: Always request detailed performance and reliability data from suppliers. Verify their claims through third-party testing or certifications, ensuring that the valves will maintain efficiency and reliability in demanding environments. Additionally, foster long-term relationships with reputable manufacturers, as they are more likely to provide consistent quality and service support.

When selecting solenoid directional control valves, it's essential to prioritize your operational needs and system requirements. These valves play a crucial role in fluid control, and understanding their functionality can significantly enhance efficiency and reliability in various applications. Key factors to consider include flow rate, pressure rating, and the specific actuation requirements of your system. By assessing these elements, you can ensure that the chosen valve will perform optimally for your unique situation.

Moreover, compatibility with existing systems and ease of maintenance are important aspects to evaluate. A valve that is easy to install and service can save considerable time and resources in the long run. It’s also advisable to look at the material construction of the valves, as this influences durability and performance, particularly in demanding environments where exposure to harsh conditions is a factor. By adhering to these best practices, you can select solenoid directional control valves that not only meet current operational demands but also provide a reliable solution for future scalability.