Leave Your Message

In the realm of fluid mechanics and automation, the efficiency and performance of systems depend significantly on the optimal functioning of Pressure Control Valves. These essential components play a critical role in regulating fluid flow and maintaining specified pressure levels, which is paramount for safety and operational excellence. According to the latest industry reports, such as those published by the Global Valve Market Study, the market for Pressure Control Valves is projected to grow substantially, driven by advancements in technology and an increasing demand for automation across various sectors, including oil and gas, water management, and manufacturing.

Effective pressure control not only enhances system reliability but also minimizes energy consumption, thereby contributing to cost savings and environmental sustainability. A recent analysis from the International Energy Agency highlights that the implementation of advanced pressure control technologies can lead to energy savings of up to 20% in large-scale industrial applications. As industries continue to emphasize efficiency and sustainability, the focus on selecting the best Pressure Control Valves becomes increasingly critical. This article aims to explore the top-performing valves on the market, shedding light on their features, benefits, and the latest innovations that drive optimal performance in demanding applications.

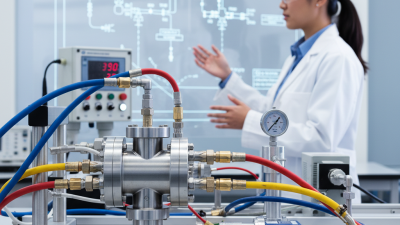

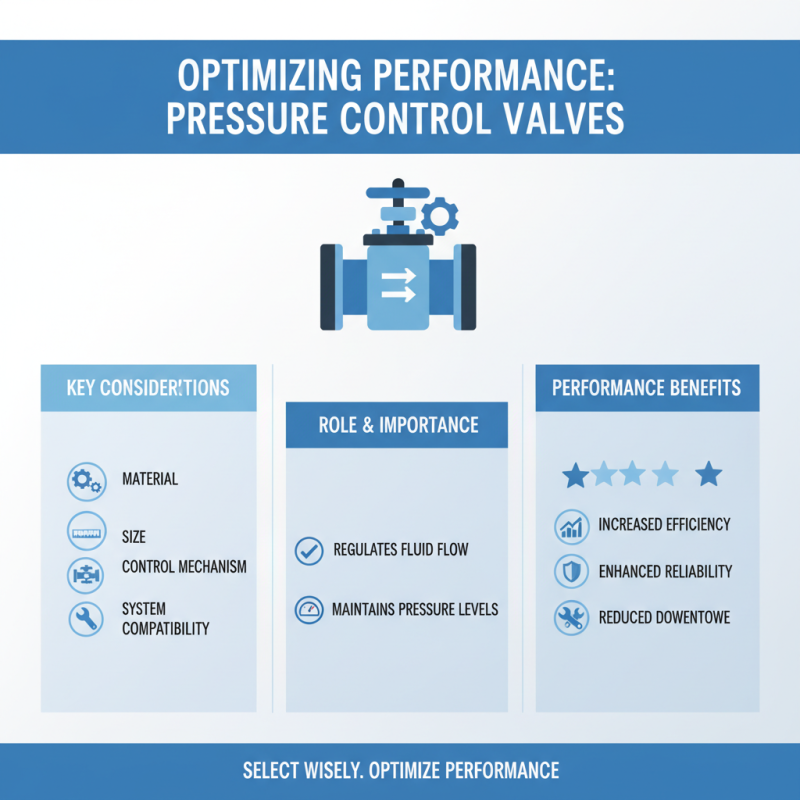

When selecting pressure control valves, several key factors should be considered to ensure optimal performance and efficiency. First and foremost is the application of the valve. Different industries may require specific features, such as corrosion resistance or compatibility with various media, making it essential to evaluate the operational environment. Understanding the pressure range and the flow rate needed for your application can also help in choosing the right valve type, whether it be a relief valve, regulator, or sequence valve.

Another critical factor is the material of the valve. The materials used in manufacturing pressure control valves can significantly affect their durability and reliability. Choosing materials that can withstand temperature fluctuations and chemical exposure is vital for long-term performance. Additionally, consider the valve size and connection type; an incorrectly sized valve can lead to inefficiencies and operational failures. Finally, the ease of maintenance and accessibility for adjustments should also be assessed, as these factors contribute to the overall operational efficiency and sustainability of the system. By taking these considerations into account, users can select pressure control valves that deliver enhanced performance tailored to their specific needs.

Pressure control valves are critical components in various industrial applications, serving to maintain system pressure and ensure optimal performance. The most common types of pressure control valves include relief valves, regulating valves, and backpressure valves. Relief valves are typically employed to prevent overpressure scenarios by automatically venting excess pressure. According to a report from Global Industry Analysts, the demand for relief valves is projected to reach $4 billion by 2025 as industries focus on safety and system reliability.

Regulating valves, on the other hand, are designed to maintain a specific downstream pressure despite fluctuations in the upstream supply or external demand changes. These valves are crucial in applications such as water treatment plants and chemical processing, where precise pressure control is necessary for efficiency and safety. The pressure regulation market is expected to grow at a CAGR of 4.5% over the next five years, driven by increased automation and the need for energy-efficient systems.

Backpressure valves play a distinct role in controlling pressure in processes that require a specific controlled flow rate, such as in oil and gas extraction and wastewater management. By maintaining a minimum pressure level, these valves ensure process stability and efficiency, thereby optimizing resource usage. Industry trends suggest a significant increase in the adoption of automated pressure control systems, highlighting the need for innovative valve solutions that enhance operational efficiency across various sectors.

When it comes to optimizing performance and efficiency in various industrial applications, selecting the right pressure control valves is crucial. These components play a vital role in regulating fluid flow and maintaining desired pressure levels. Various brands and models stand out in the market, offering innovative features and reliable performance. Key considerations when choosing a pressure control valve include the valve's material, size, and the specific control mechanism it employs, as well as its compatibility with the systems it is intended to regulate.

Many top manufacturers focus on delivering products designed with advanced technology, ensuring accuracy and durability. The best models often include features such as adjustable pressure settings, robust sealing materials, and user-friendly interfaces. Additionally, some valves are tailored for specific industries, providing specialized performance in applications ranging from water treatment to oil and gas processing. Understanding these distinctions is essential for users aiming to enhance their operational efficiency while minimizing maintenance costs and downtime. Selecting from among these high-quality offerings can significantly impact overall system performance and longevity.

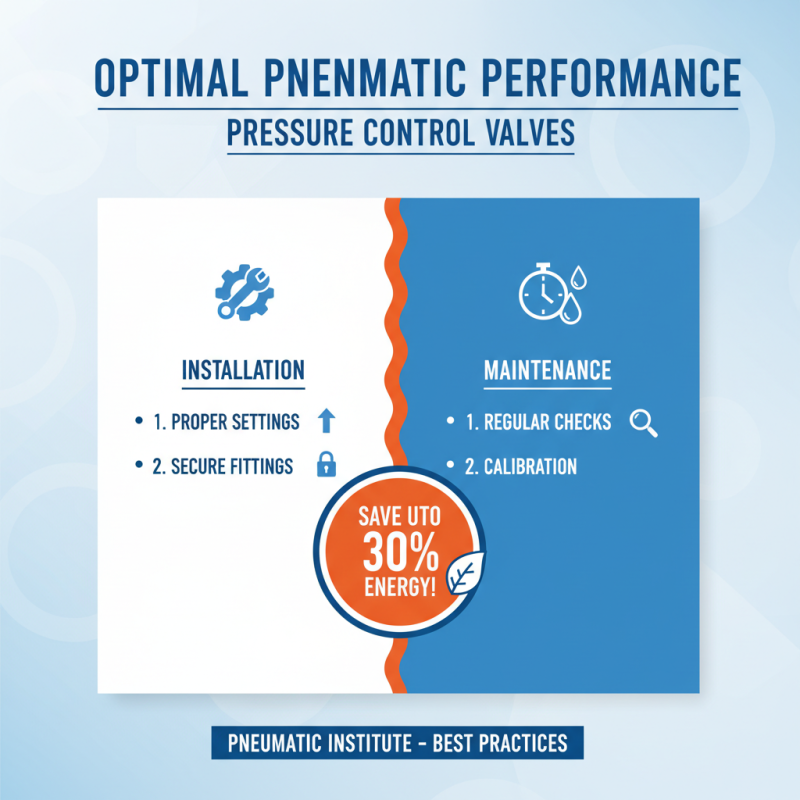

Proper installation and maintenance of pressure control valves are crucial for ensuring optimal performance and efficiency in various applications. According to the Pneumatic Institute, improper valve settings can lead to a loss of system efficiency by up to 30%, resulting in increased energy consumption and operating costs. Therefore, following best practices during installation and regular maintenance is essential.

One important tip for installation is to ensure that the valve is positioned correctly within the system. Ideally, pressure control valves should be installed in a location that minimizes the potential for vibration and turbulence, which can affect their performance. Additionally, utilizing compatible materials and sealing methods helps prevent leaks and ensures the integrity of the system. Maintenance should include regular inspections to check for wear, leaks, and proper operation, ensuring that any potential issues are addressed proactively.

To maintain optimal performance, it is recommended to schedule routine servicing at least once a year, according to industry standards. During maintenance, specific attention should be given to the valve seats and seals, as these components are critical for maintaining accurate pressure regulation. Additionally, debris and foreign particles should be cleared from the valve assembly to avoid any hindrance in operation. Implementing these installation and maintenance tips not only helps in achieving better efficiency but also extends the lifespan of the pressure control valves, thereby reducing overall system costs.

Pressure control valves are essential components in various industrial and residential applications, ensuring that systems operate within optimal pressure ranges. However, users often encounter common issues that can hinder efficiency and performance. One prevalent problem is valve sticking, which can occur due to dirt accumulation or inadequate lubrication. This not only affects the valve's responsiveness but can also lead to pressure fluctuations throughout the system.

To mitigate this issue, regular maintenance is vital. Inspecting and cleaning pressure control valves should be part of a routine schedule to ensure they remain in optimal condition. Additionally, employing the right type of lubrication can help prevent sticking and extend the valve's lifespan.

Another common issue involves incorrect calibration, which can result in inaccurate pressure regulation. To avoid this problem, it's essential for operators to regularly check and adjust the calibration settings according to the manufacturer's specifications. Implementing a monitoring system can also help visually track changes in pressure and identify deviations from expected performance.

Tips: Always keep spare parts on hand for quick replacements and consider using strainers to filter out debris that may affect valve performance. Educating staff on the proper operation and regular checks can significantly reduce the likelihood of these common issues arising.