Leave Your Message

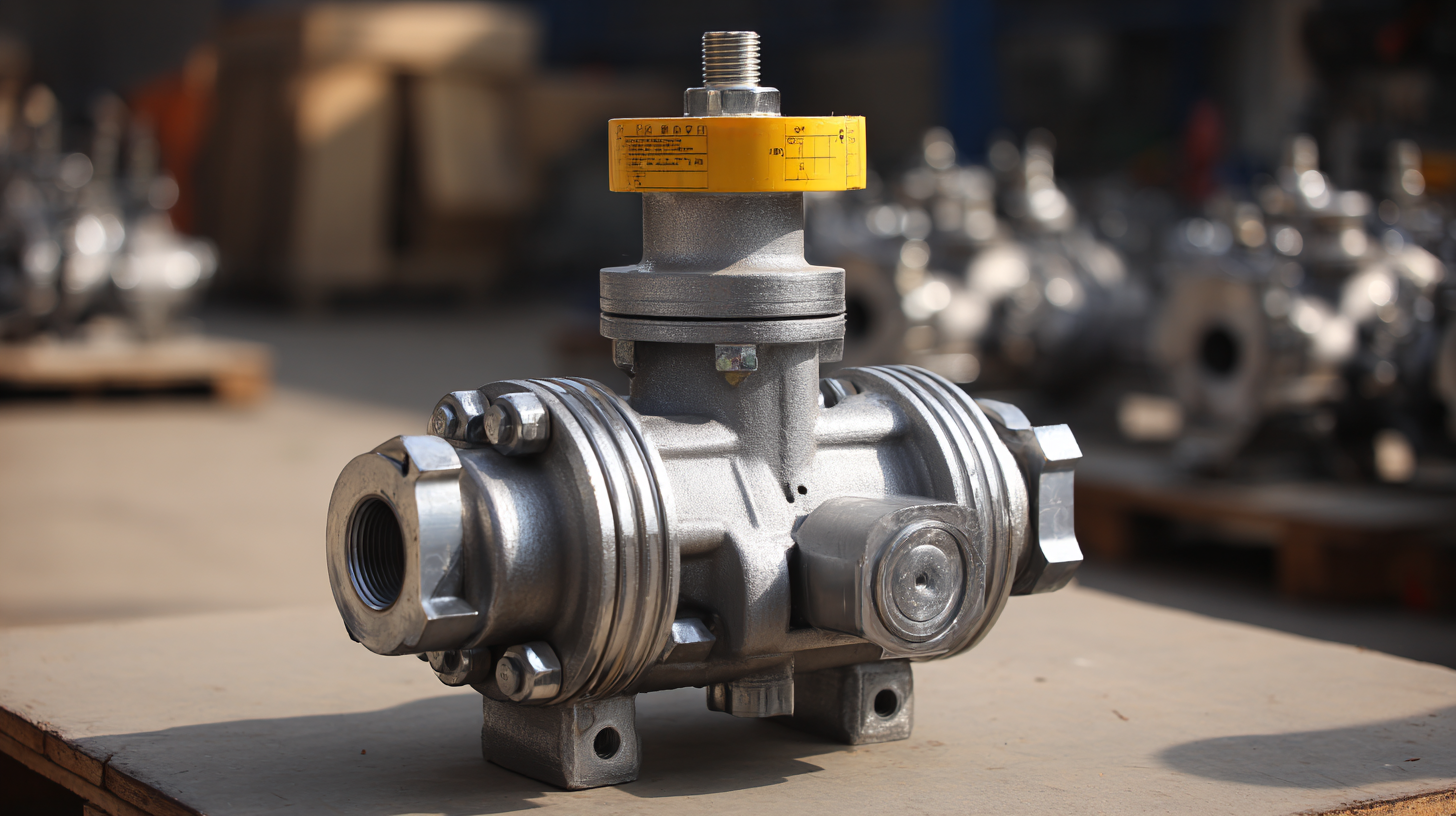

In today's rapidly evolving industrial landscape, the demand for efficient and reliable control systems is paramount, particularly in fluid power applications. Among the various components that play a crucial role in ensuring system performance, the Pilot Operated Check Valve stands out as a vital solution. According to a recent market research report by Global Industry Analysts, the global valve market is projected to reach an impressive USD 85 billion by 2027, driven by the increasing need for automation and precision in various sectors. The Pilot Operated Check Valve, known for its ability to prevent backflow while allowing for smooth and controlled flow in hydraulic and pneumatic systems, has gained significant traction among industry professionals. Its superior design not only enhances operational efficiency but also contributes to safety and reliability, making it a top choice for many leading manufacturers, including high-quality factories in China that cater to the global market.

Pilot operated check valves (POCVs) are increasingly recognized as essential components in fluid control systems across various industries. Their unique design incorporates a pilot valve, which allows for flow regulation while ensuring that backflow is effectively prevented. According to a report by Market Research Future, the global valve market is expected to reach $90 billion by 2025, with POCVs projected to capture a significant share due to their enhanced functionality and reliability.

Pilot operated check valves (POCVs) are increasingly recognized as essential components in fluid control systems across various industries. Their unique design incorporates a pilot valve, which allows for flow regulation while ensuring that backflow is effectively prevented. According to a report by Market Research Future, the global valve market is expected to reach $90 billion by 2025, with POCVs projected to capture a significant share due to their enhanced functionality and reliability.

One of the critical advantages of pilot operated check valves is their ability to provide precise control over fluid flow. This is especially important in applications such as hydraulic systems, where even slight variations in pressure can lead to inefficient operation or equipment damage. The Hydraulic Institute reports that systems employing POCVs can reduce energy consumption by up to 20%, making them not only a practical choice but also an environmentally friendly one. Beyond energy savings, the inherent safety features of these valves prevent pressure surges and system failures, ensuring operational continuity and longevity.

Additionally, the adaptability of pilot operated check valves makes them suitable for various fluids and conditions, from high-pressure hydraulic lines to low-flow applications. Their efficiency in handling diverse scenarios positions them as the go-to solution for engineers and system designers seeking to optimize their fluid control systems. With their proven benefits and robust performance, it's clear why pilot operated check valves are becoming a preferred choice in the industry.

Pilot operated check valves offer significant advantages that make them a preferred choice in various industrial applications. One of the primary benefits is their ability to provide superior seal performance. According to a report by the Hydraulic Institute, pilot operated check valves can minimize leakage rates to as low as 1% of flow, drastically reducing waste and enhancing system efficiency. This remarkable sealing capability not only contributes to energy savings but also extends the lifespan of equipment by preventing unnecessary wear and tear.

Additionally, the versatility of pilot operated check valves cannot be overlooked. They are designed to handle high pressure and flow variations, making them ideal for dynamic systems where flow conditions may change. A study published by the International Journal of Fluid Mechanics highlighted that these valves can efficiently manage pressures up to 350 bar, showcasing their suitability for demanding hydraulic applications. By integrating pilot operated check valves into your projects, you gain a robust solution that enhances operational reliability while minimizing maintenance needs.

| Feature | Benefit | Application | Cost Efficiency |

|---|---|---|---|

| Non-Return Functionality | Prevents backflow, ensuring system integrity | Hydraulic systems | Reduced maintenance costs |

| Pilot Operation | Improved control of flow rates | Industrial automation | Increased operational efficiency |

| Space Saving Design | Minimal footprint for installation | Tight spaces in factories | Lower installation costs |

| Durable Construction | Long lifespan and reliability | Critical infrastructure systems | Reduced replacement frequency |

| Wide Range of Sizes | Flexibility for various applications | Custom installations | Cost-effective solutions |

| Easy Maintenance | User-friendly design allows quick service | Regular operational environments | Saves time and service costs |

| Versatile Applications | Suitable for various fluids, including oils and water | Different industrial sectors | Reduced project costs |

Pilot operated check valves (POCVs) play a pivotal role in enhancing safety and reliability in various operational settings, particularly in industries such as hydraulics and fluid power. According to a report by the Fluid Power Journal, improper flow management can lead to equipment failures that account for nearly 30% of unscheduled downtime in hydraulic systems. POCVs address this issue effectively by allowing unrestricted flow in one direction while preventing backflow, thereby safeguarding against potential operational hazards.

Moreover, the inherent design of POCVs helps to maintain system stability under fluctuating pressure conditions. Industry statistics indicate that systems equipped with advanced pilot operated check valves experience a 15-20% improvement in energy efficiency due to reduced hydraulic losses. This efficiency not only enhances operational reliability but also contributes to lower overall maintenance costs. Enhanced performance can lead to a significant reduction in leaks and failures, ultimately promoting a safer work environment.

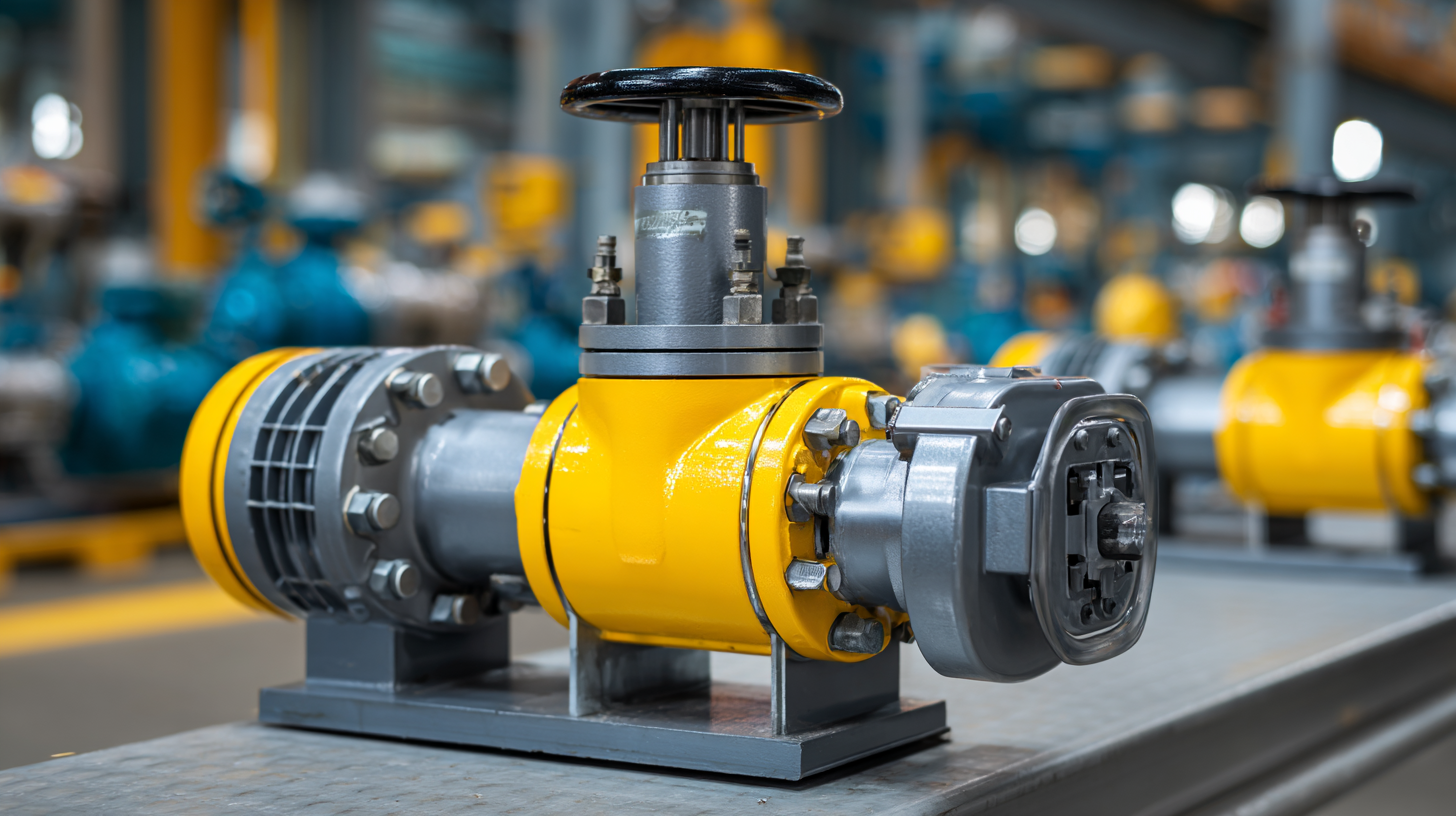

When it comes to choosing between pilot operated check valves and traditional check valves, it's essential to understand the fundamental differences and advantages each type presents. Traditional check valves, while effective in preventing backflow, often have limitations concerning pressure changes and flow rates. In contrast, pilot operated check valves can adapt to varying system conditions with greater precision. According to a study by the Hydraulic Institute, pilot operated check valves can reduce energy loss by as much as 30%, making them a more efficient choice for complex systems.

Furthermore, the operational flexibility of pilot operated check valves is a significant advantage in dynamic environments. Unlike their traditional counterparts, which can be prone to slamming and require higher pressure differentials to function correctly, pilot operated check valves utilize a pilot signal to control flow, leading to smoother operation and reduced wear. The International Association for Hydraulic Research suggests that using pilot operated check valves in hydraulic circuits can enhance system reliability by up to 25%, minimizing downtime and maintenance costs. This adaptability not only enhances performance but also extends the lifespan of the valve, resulting in long-term cost savings for operators.

Pilot operated check valves are essential components in various industries, supporting operational efficiency and safety across many applications. In hydraulic systems, for example, these valves ensure one-way flow and prevent backflow, which can cause damage to sensitive equipment. Their ability to maintain high pressure while allowing smooth operation makes them invaluable in manufacturing settings, where machinery relies on precise fluid control.

Moreover, in the water management sector, pilot operated check valves play a crucial role in controlling water flow in irrigation systems and municipal water supply networks. By preventing reverse flow, they safeguard infrastructure and ensure that water is distributed efficiently.

Additionally, in the oil and gas industry, these valves enhance safety by controlling fluid movement and preventing accidental spills. Their versatility and reliability make pilot operated check valves a top choice for professionals seeking to optimize their systems and protect their investments.