Leave Your Message

In the dynamic landscape of industrial applications, ensuring both safety and efficiency is paramount. One critical component that plays a vital role in achieving these goals is the Hydraulic Lock. This device serves as a safeguard against unintended movements and failures in hydraulic systems, significantly reducing the risk of accidents in high-stakes environments.

Often overlooked, the Hydraulic Lock not only enhances operational reliability but also helps in maintaining compliance with industry standards and certifications, essential for companies facing stringent import and export regulations. By integrating a quality Hydraulic Lock into their operations, businesses can optimize productivity while prioritizing the safety of their workforce, making it an indispensable tool in contemporary industrial settings.

In this blog, we explore seven compelling reasons why investing in the best Hydraulic Lock can transform industrial safety and efficiency.

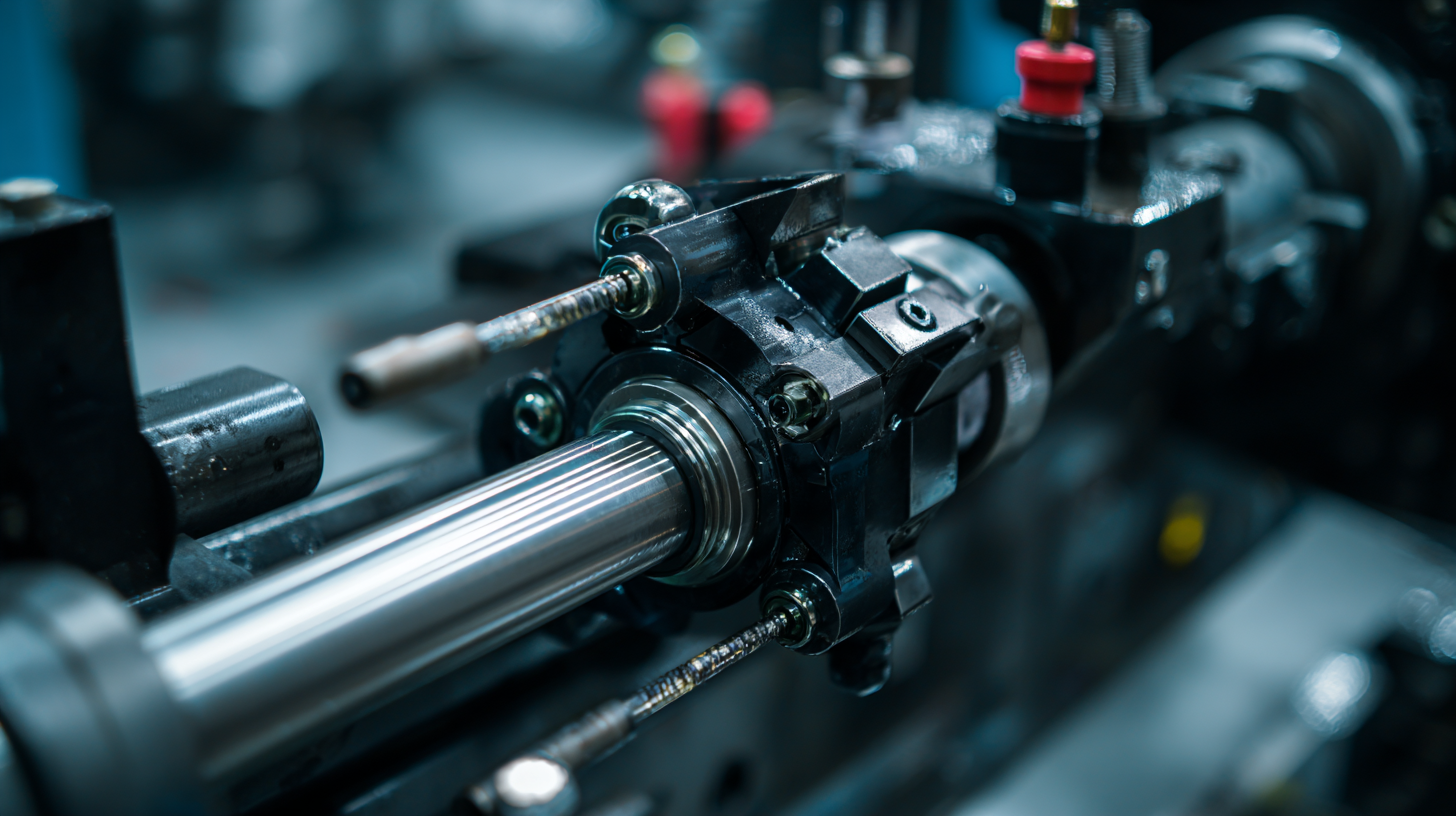

In industrial settings, the choice of hydraulic locks can significantly influence operational safety and efficiency. High-quality hydraulic locks feature robust construction materials, often using high-strength steel or corrosion-resistant alloys that enhance durability and reliability. According to a report by MarketsandMarkets, the hydraulic equipment market is projected to reach $49.2 billion by 2025, highlighting the increasing reliance on effective hydraulic solutions. These locks also incorporate advanced sealing technologies that prevent fluid leaks, ensuring consistent performance under heavy loads.

Another critical aspect of hydraulic locks is their ergonomics and user-friendly design. This includes features like quick-release mechanisms and intuitive controls that enable operators to quickly secure or release machinery, minimizing downtime and enhancing workflow efficiency. A recent study from the International Journal of Industrial Ergonomics emphasizes that well-designed hydraulic systems can reduce operational errors by up to 35%. In turn, this leads to safer work environments and decreases the likelihood of accidents, proving that investing in high-quality hydraulic locks is not only a matter of compliance but also a strategic advantage for any industrial operation.

| Feature | Description | Impact on Safety | Impact on Efficiency |

|---|---|---|---|

| Robust Design | Built to withstand heavy loads and harsh conditions. | Minimizes risk of structural failures. | Ensures consistent performance over time. |

| Quick Engagement | Rapid lock activation when needed. | Reduces chances of accidents during operation. | Improves turnaround time for operations. |

| Integrated Safety Features | Includes fail-safes and emergency releases. | Enhances operator safety during emergencies. | Reduces downtime caused by safety checks. |

| Corrosion Resistance | Made from materials that resist corrosive environments. | Increases longevity and reliability of equipment. | Decreases maintenance frequency and costs. |

| Versatility | Compatible with various hydraulic systems. | Enhances safety in multi-purpose applications. | Allows for efficient use across different operations. |

| Easy Maintenance | Simplified design for quick service access. | Reduces risk of accidents due to overlooked maintenance. | Minimizes operational halts during maintenance. |

| Precision Locking Mechanism | Provides a secure, precise locking capability. | Increases confidence in load stability. | Enhances workflow by ensuring reliability in load handling. |

Hydraulic locks play a pivotal role in enhancing workplace safety standards across various industrial applications. These devices provide a secure method of controlling machinery and equipment, significantly reducing the risks associated with hydraulic systems. According to recent industry reports, the Anti-Lock Braking System market is projected to grow substantially by 2032, highlighting the increasing emphasis on safety in machinery across multiple sectors. The integration of hydraulic locks not only bolsters safety but also ensures reliability in operations, allowing businesses to maintain high productivity levels while minimizing potential hazards.

Hydraulic locks play a pivotal role in enhancing workplace safety standards across various industrial applications. These devices provide a secure method of controlling machinery and equipment, significantly reducing the risks associated with hydraulic systems. According to recent industry reports, the Anti-Lock Braking System market is projected to grow substantially by 2032, highlighting the increasing emphasis on safety in machinery across multiple sectors. The integration of hydraulic locks not only bolsters safety but also ensures reliability in operations, allowing businesses to maintain high productivity levels while minimizing potential hazards.

In addition to their safety benefits, hydraulic locks contribute to operational efficiency by preventing accidental device activation. With hydraulic structures being designed to meet modern resilience standards, the implementation of such safety devices aligns with the industry's push towards sustainable and safe practices. Research shows that incorporating advanced safety features, similar to those found in modern vehicles, can significantly reduce the likelihood of workplace accidents. As companies strive to adhere to stringent safety regulations, the adoption of hydraulic locks is becoming increasingly critical in maintaining high workplace safety standards and ensuring smoother operational workflows.

Hydraulic locks have become critical components in enhancing operational efficiency across various industrial applications. By providing a secure and effective means of locking hydraulic circuits, they not only prevent unintended movement of machinery but also streamline the functionality of complex systems like electrical submersible pumps (ESPs) that handle multiphase flow. This reliability significantly reduces downtime and maintenance needs, which is crucial for maintaining productivity in energy-intensive environments.

Moreover, the impact of hydraulic locks on energy consumption should not be overlooked. Recent studies comparing motor-controlled and valve-controlled cylinders in knuckle boom crane operations reveal substantial differences in energy usage, highlighting how optimized hydraulic systems can lead to more sustainable practices. As industries increasingly adopt electric prime movers alongside hydraulic technology, there is a clear trend toward enhancing performance while minimizing energy expenses. This integrated approach not only boosts efficiency but also aligns with broader goals of operational sustainability and cost reduction.

Preventative maintenance practices are crucial for enhancing the longevity and performance of hydraulic locks in industrial applications. According to a report by the International Fluid Power Society, inadequate maintenance can lead to equipment failures that account for approximately 30% of unplanned downtime in hydraulic systems. Regular inspections, lubrication, and timely replacements of worn parts not only extend the lifespan of hydraulic locks but also contribute significantly to workplace safety.

Implementing a proactive maintenance schedule can reduce the risk of catastrophic failures. The National Safety Council estimates that properly maintained hydraulic equipment can save organizations up to 25% in repair costs. Key maintenance practices include monitoring fluid levels, checking for leaks, and ensuring that seals and gaskets are intact. By adhering to these practices, industries can enhance operational efficiency and minimize potential hazards associated with malfunctioning hydraulic locks, ultimately leading to safer and more productive workplaces.

In various industrial settings, hydraulic locks play a crucial role in enhancing operational safety and efficiency. For instance, in the construction industry, a leading company implemented hydraulic locks in their lifting equipment. This adjustment led to a remarkable reduction in accidental drops, ensuring worker safety and minimizing project delays. They reported an impressive 30% decrease in safety incidents, showcasing the efficacy of hydraulic locks in real-world applications.

Another success story comes from the manufacturing sector, where a company faced frequent machinery malfunctions due to improper locking mechanisms. By upgrading to hydraulic locks, they achieved a significant increase in uptime and productivity. The streamlined locking system allowed for quick adjustments while maintaining safety standards, leading to a 20% boost in production metrics.

**Tip:** Regular maintenance of hydraulic locks is essential for sustaining their effectiveness and ensuring safety. Implement a routine inspection protocol to check for wear and tear.

**Tip:** Train your employees on the proper use of hydraulic locks to maximize efficiency and minimize the risk of accidents. Establish clear guidelines for operating equipment equipped with these locks.