Leave Your Message

In the ever-evolving landscape of industrial applications, the adoption of advanced technologies is paramount for enhancing efficiency and safety. Among these innovations, Remote Control Relief Valves (RCRVs) have emerged as a critical component for managing pressure and ensuring system integrity. According to a recent industry report by the International Society of Automation, the implementation of remote control systems in pressure management can lead to a 30% reduction in operational risks, significantly bolstering process reliability. As industries rapidly embrace automation, RCRVs stand out for their ability to provide precise control over pressure release, minimizing the potential for hazardous overpressure situations.

Dr. Helen Maslow, a leading expert in fluid dynamics and industrial safety, emphasizes the importance of RCRVs in modern systems: "The deployment of Remote Control Relief Valves not only enhances safety measures but also streamlines operational efficiency, empowering industries to reduce downtime and optimize resource management." This assertion is supported by findings from the Hydraulic Institute, which indicate that industries utilizing RCRVs experience an increase in overall system performance by up to 25%. As we delve into the top 10 benefits of using Remote Control Relief Valves in industrial applications, it becomes evident that these devices are revolutionizing pressure management, ensuring safer and more efficient industrial operations.

Remote control relief valves are gaining traction in industrial settings due to their numerous advantages that enhance operational efficiency and safety. One of the key benefits is the ability to manage pressure remotely, which allows operators to monitor and adjust settings from a safe distance. This capability minimizes the need for personnel to be physically present in potentially hazardous areas, significantly reducing the risk of accidents and improving workplace safety.

Furthermore, these valves provide precise control over pressure relief operations, ensuring that systems operate within optimal parameters. This precision helps in preventing equipment damage and unplanned downtime, leading to increased productivity. The integration of remote control technology also streamlines maintenance procedures, as operators can diagnose and resolve issues more effectively without interrupting operations. Overall, the use of remote control relief valves not only enhances safety and efficiency but also contributes to cost savings for industrial facilities.

Remote control relief valves have gained significant attention in industrial applications due to their enhanced safety features. These valves are designed to operate remotely, providing operators with the ability to monitor and control pressure levels without direct intervention. This is especially crucial in high-risk environments where human exposure to hazardous materials could pose serious safety threats. By allowing for remote operation, these valves minimize the risk of accidents and improve overall workplace safety.

In addition to reducing human exposure, remote control relief valves are equipped with advanced safety mechanisms that ensure consistent pressure relief even under emergency conditions. They are designed to sense pressure changes in real-time, automatically adjusting to maintain optimal settings. This proactive approach not only prevents equipment failure but also safeguards personnel from potential harm.

**Tips:** When implementing remote control relief valves, ensure that your team is adequately trained on their operation and safety features. Regular maintenance checks can significantly enhance the reliability of these systems. Additionally, integrating remote monitoring technology can provide real-time data, allowing for more informed decision-making and timely interventions when necessary.

| Benefit | Description | Impact on Safety |

|---|---|---|

| Remote Monitoring | Allows for real-time monitoring of pressure levels. | Enhances early detection of potential overpressure situations. |

| Automated Control | Enables automated adjustments based on system conditions. | Reduces human error in critical pressure management. |

| Emergency Response | Can be activated remotely in case of emergencies. | Improves safety response times in hazardous situations. |

| Increased Reliability | Designed for high performance and minimal failure rates. | Ensures more dependable operation under varying conditions. |

| Reduced DownTime | Less frequent repairs and maintenance required. | Minimizes the risk of unsafe conditions due to failures. |

| Better Workflow Integration | Easily integrates with existing industrial control systems. | Enhances safety through streamlined processes. |

| Data Logging | Records pressure and operational data for analysis. | Facilitates safety audits and compliance checks. |

| Customizable Settings | Settings can be tailored to specific system requirements. | Ensures the most effective safety parameters are in place. |

| Investment Cost Savings | Long-term savings due to fewer incidents and repairs. | Enhances overall operational safety and profitability. |

| Enhanced Operator Safety | Remote operation reduces the need for personnel in dangerous areas. | Significantly lowers the risk of accidents to staff. |

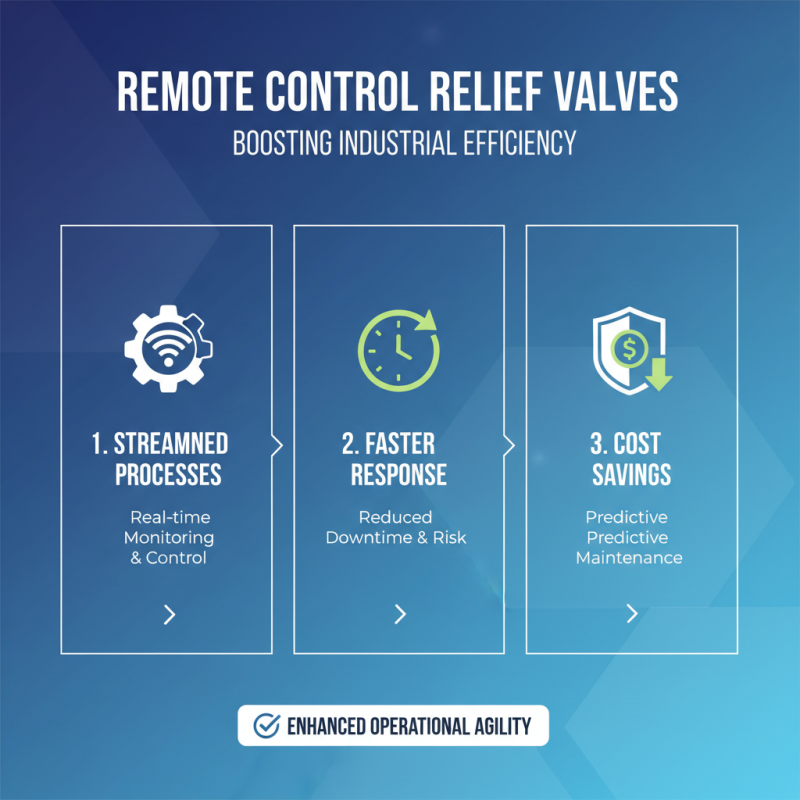

The adoption of remote control relief valves in industrial applications significantly enhances operational efficiency by streamlining processes and reducing response times. By enabling real-time monitoring and control of pressure relief systems, these valves allow operators to make informed decisions promptly. This agility not only minimizes the risk of equipment failure but also significantly cuts down on maintenance costs, as potential issues can be addressed before they escalate into more severe problems.

In addition to improving responsiveness, remote control valves facilitate better data collection and analysis. With integrated sensors and communication technologies, these systems provide critical insights into performance metrics and operational parameters. This data-driven approach empowers industries to optimize their workflows, leading to increased productivity and reduced downtime. Moreover, the remote operation capability enhances safety by allowing adjustments from a safe distance, thereby protecting personnel from hazardous environments. This combination of efficiency and safety positions remote control relief valves as a vital component in modern industrial operations.

Remote control relief valves (RCRVs) are increasingly recognized for their flexibility in system design across various industrial applications. By allowing for remote monitoring and control, these valves enable operators to manage pressure relief in real time, facilitating quicker responses to potential hazards. According to a report by the American Society of Mechanical Engineers, using RCRVs can reduce the risk of overpressure incidents by up to 50%, underscoring their significance in maintaining safety standards while enhancing operational efficiency.

One of the prime advantages of RCRVs lies in their adaptability to complex systems. Industries that require varied pressure settings, such as oil and gas or chemical processing, benefit immensely from the precision these valves offer. The ability to fine-tune pressures remotely allows for more streamlined workflows and less downtime during maintenance. A study by the International Society of Automation indicates that facilities using advanced remote control systems have experienced a 30% increase in system reliability.

Tips: When integrating RCRVs into your systems, prioritize compatibility with existing control systems to maximize efficiency. Regular training on remote management tools can enhance operator confidence and proficiency, leading to improved safety and system management. Additionally, conducting periodic reviews of pressure settings can help in identifying trends and optimizing the use of RCRVs for better performance.

Remote control relief valves offer significant cost-effectiveness in industrial applications. By allowing for automated pressure management, these valves reduce the need for manual intervention, which can be both time-consuming and costly. In environments where precision and safety are paramount, the integration of remote control systems minimizes downtime due to human error and enhances overall operational efficiency. The automation of pressure relief systems not only optimizes performance but also ensures compliance with safety standards, thereby avoiding the potential financial repercussions of regulatory violations.

In addition to their cost-saving advantages, remote control relief valves simplify maintenance routines. Traditional relief valves often require regular checks and manual adjustments, leading to increased labor costs and extended periods of maintenance. Conversely, remote control valves can be monitored and adjusted from a centralized location, enabling predictive maintenance practices. This proactive approach not only extends the lifespan of the equipment but also significantly cuts down on emergency repairs and related expenses. Ultimately, the implementation of remote control relief valves attracts long-term savings through reduced operational risks and streamlined maintenance processes.