Leave Your Message

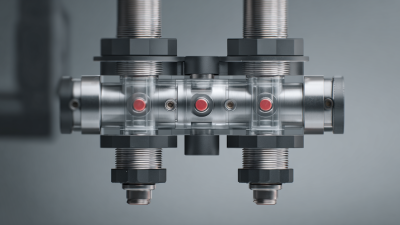

In the rapidly evolving landscape of modern systems, the integration of innovative components plays a crucial role in enhancing performance and efficiency. One such component that has garnered significant attention is the Buffered Logic Element Valve. These valves represent a significant advancement in engineering design, combining the principles of logic control with buffering technology to deliver superior functionality. This introduction aims to explore the core principles behind Buffered Logic Element Valves and their wide-ranging applications in various industries, from fluid dynamics to automation.

Buffered Logic Element Valves are increasingly essential in industrial automation, primarily due to their ability to enhance efficiency and reliability in various applications. Recent studies highlight that the need for robust automation solutions is driven by the growing need to reduce gas flaring and other environmental impacts associated with traditional oil and gas production. According to the International Energy Agency, global gas flaring accounted for around 140 billion cubic meters in 2021, emphasizing the urgency for effective systems that can monitor and manage gas emissions. Buffered Logic Element Valves can play a pivotal role in these contexts by enabling precise control over fluid dynamics, thereby optimizing processes and contributing to sustainability.

Moreover, the advent of technologies such as digital pneumatic logic in soft robotic actuators showcases the transformative potential of buffered logic elements in automation. Soft robotics, which aim to replicate the versatility of natural movements, require nuanced control capabilities provided by such valves. In a recent report from the Robotics Research Institute, it was indicated that integrating buffered logic with textile-based pneumatic computers allows for unprecedented user interaction and adaptability in wearable robots. These innovations not only enhance functionality but also ensure a greater alignment with modern environmental standards.

Buffered Logic Element (BLE) valves are increasingly recognized for their role in enhancing energy efficiency across various industrial systems. According to a recent report by the International Energy Agency (IEA), optimizing valve performance can lead to an energy consumption reduction of up to 30% during peak operations. This efficiency is achieved through the BLE's ability to precisely control fluid flow while minimizing pressure drops, which translates to lower energy costs and reduced greenhouse gas emissions.

In addition to immediate energy savings, BLE valves contribute to improved overall system reliability. A study from the American Society of Mechanical Engineers (ASME) highlighted that the integration of buffered logic elements can extend the lifespan of mechanical components by as much as 25%, as they reduce wear and tear caused by excessive pressure fluctuations. This longevity not only lowers maintenance costs but also ensures uninterrupted services in critical applications, further emphasizing the value of adopting BLE technology in modern systems.

Buffered Logic Element (BLE) valves are revolutionizing modern systems by offering enhanced performance compared to traditional valves. One of the key differences lies in their ability to manage flow more efficiently, allowing for faster response times and improved control. While traditional valves can struggle with varying pressures and flow rates, BLE valves utilize a buffered logic system, which intelligently adapts to changes in the system, providing consistency that traditional systems often lack.

Tips: When selecting valves for your application, consider the specific needs of your system. BLE valves provide superior adaptability and control, so they might be the right choice if your application involves fluctuating conditions. Assessing the long-term costs and benefits of BLE valves versus traditional models can also reveal significant savings, particularly in maintenance and operational efficiency.

In addition, BLE valves facilitate better integration with automated systems. Unlike traditional valves, which require manual adjustments and monitoring, BLE valves can seamlessly communicate with control systems, reducing human error and downtime. This not only enhances productivity but also ensures a smoother operation overall. Implementing BLE valves can lead to more reliable performance in critical applications, showcasing the importance of embracing advanced technologies in modern engineering.

The advancements in Buffered Logic Element Valve technology are fostering significant innovations in the valve industry, particularly as the global market moves towards high-end and intelligent solutions. The global valve market, which is projected to expand from approximately $8.347 billion in 2024 to $13.182 billion by 2032, showcases a promising compound annual growth rate (CAGR) of 5.9%. This growth is driven in part by increasing demand for sophisticated automation and control systems in various sectors, including aerospace and pharmaceuticals.

In China, government policies aimed at supporting the development of smart control valves are creating a conducive market environment, benefiting manufacturers in the valve industry. The Chinese industrial valve manufacturing market is estimated to grow from CNY 756.3 billion to CNY 1,033.6 billion between 2018 and 2023. Moreover, innovations such as the recently patented AI-driven valve actuators highlight the industry's shift towards smart solutions, potentially enhancing operational efficiency and system integration. As the industry evolves, the emphasis on Buffered Logic Element Valves and their capabilities is expected to play a crucial role in meeting the demands of modern systems while remaining adaptable to future technological developments.

Buffered Logic Element Valves (BLEVs) represent a significant advancement in modern fluid control systems, yet their implementation is not without challenges. One prominent issue is the integration of these valves into existing systems. According to a report by

MarketsandMarkets, the global demand for advanced valve technology is expected to reach USD 46 billion by 2026, indicating a surge in modernization efforts. However, legacy systems often use outdated technology, making the retrofit process complicated. For instance, interoperability issues can arise, requiring engineers to navigate between old and new technologies, potentially leading to increased installation times and costs.

Another challenge is the necessity for precise calibration and control mechanisms. The American Society of Mechanical Engineers (ASME) highlights that suboptimal valve performance can lead to fluid dynamics inefficiencies, which not only affects system reliability but also increases maintenance costs. Implementing advanced sensors and predictive analytics can mitigate these issues, as they provide real-time data and monitoring capabilities. A recent study showed that integrating IoT-enabled sensors with BLEV technology can enhance operational efficiency by up to 30%, demonstrating that while challenges exist, solutions are readily available to improve functionality and reliability in modern systems.