Leave Your Message

In the ever-evolving automotive industry, selecting the right auto parts hydraulic valve is crucial for enhancing operational efficiency and ensuring optimal performance. According to a report by MarketsandMarkets, the global hydraulic valves market is projected to grow from USD 4.11 billion in 2021 to USD 5.53 billion by 2026, reflecting a CAGR of 6.2%. This growth underscores the increasing importance of high-quality hydraulic components in modern vehicles. Choosing the appropriate auto parts hydraulic valve can boost system efficiency by up to 30%, significantly reducing operational costs and improving productivity. This blog will provide seven essential tips for selecting the right hydraulic valve, helping automotive professionals and enthusiasts make informed decisions that can lead to substantial performance gains and reliability in their hydraulic systems.

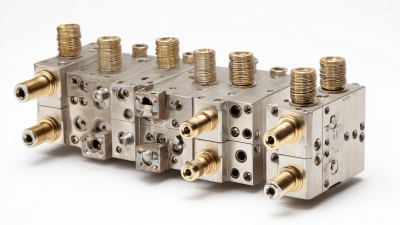

Hydraulic valves play a crucial role in the functionality of auto parts, serving as the heart of hydraulic systems. Their primary function is to control the flow and pressure of hydraulic fluid, enabling various components to operate smoothly and efficiently. By directing fluid to specific areas, hydraulic valves ensure that power is transmitted precisely where it’s needed, preventing system failures and enhancing overall vehicle performance. Understanding how these valves work can significantly impact the effectiveness of your auto parts.

Hydraulic valves play a crucial role in the functionality of auto parts, serving as the heart of hydraulic systems. Their primary function is to control the flow and pressure of hydraulic fluid, enabling various components to operate smoothly and efficiently. By directing fluid to specific areas, hydraulic valves ensure that power is transmitted precisely where it’s needed, preventing system failures and enhancing overall vehicle performance. Understanding how these valves work can significantly impact the effectiveness of your auto parts.

Selecting the right hydraulic valve is essential in improving the efficiency of your automotive systems by up to 30%. The key lies in understanding the different types of valves available, such as check valves, directional control valves, and pressure relief valves, each designed for specific applications. The correct valve can optimize performance, reduce wear on components, and extend the lifespan of your vehicle’s hydraulic system. Therefore, having a clear grasp of how hydraulic valves function will empower you to make informed decisions when upgrading or replacing auto parts, ultimately boosting your vehicle's efficiency and reliability on the road.

When selecting the right hydraulic valve for your auto parts application, several key factors can significantly influence efficiency and performance. Firstly, understanding the flow rate requirements is crucial. According to a study by the Hydraulic Institute, optimizing the flow rate can improve system efficiency by up to 30%. Ensuring that the valve can handle the required flow without pressure loss is essential for maintaining optimal performance.

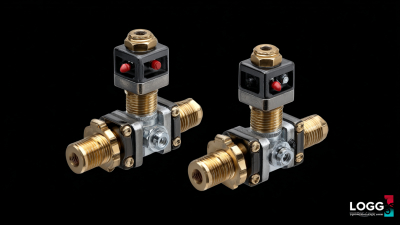

Another important factor is the valve’s compatibility with the fluid being used. Factors such as viscosity and temperature can affect the performance of hydraulic valves. Selecting a valve made from materials resistant to corrosion and wear is vital. Manufacturers like Parker Hannifin emphasize that choosing the right materials can enhance the lifespan of hydraulic components significantly, sometimes doubling it.

Tip 1: Always consult with manufacturer specifications and performance data to ensure the valve meets your application's specific demands. Tip 2: Consider investing in valves with adjustable settings to accommodate varying operational conditions, which can lead to better overall system efficiency. Understanding these key factors will lead to more informed decisions and enhanced efficiency in your hydraulic systems.

When it comes to optimizing the performance of your hydraulic system, selecting the right type of hydraulic valve is crucial. There are several types of hydraulic valves, each designed with specific applications in mind. For instance, ball valves offer excellent sealing but can be less efficient in flow control compared to spool valves, which provide precise modulation of flow and pressure. Understanding the differences is essential to ensure that the selected valve aligns with your operational requirements, ultimately enhancing system efficiency.

In addition to ball and spool valves, other variants such as check valves and relief valves play pivotal roles in maintaining system integrity. Check valves prevent backflow, ensuring a one-directional flow that can safeguard against potential damage to the hydraulic system. On the other hand, relief valves are integral in protecting the system from pressure surges, thus prolonging the life of the machinery. Evaluating the specific needs of your operation will guide you in selecting the most suitable hydraulic valve type, leading to improved performance and a potential efficiency boost of up to 30%.

Proper maintenance of hydraulic valves is essential for maximizing their lifespan and efficiency. According to a report by the International Journal of Fluid Power, regular maintenance can reduce the failure rate of hydraulic systems by up to 25%. This statistic underscores the importance of keeping hydraulic valves in optimal condition to avoid costly downtimes and replacements.

One key maintenance tip is to regularly check and clean the hydraulic fluid filters. Contaminated fluid can lead to premature wear and tear on the valve components. Industry experts recommend replacing hydraulic fluid every 1,000 hours of operation or at least once a year, whichever comes first, to ensure smooth functioning and reliability.

Another essential tip is to monitor for external leaks and pressure drops. Small leaks can escalate into major problems if not addressed promptly. It's advisable to perform routine inspections, looking for signs of leakage and ensuring that the valve is properly calibrated. Implementing these practices can boost the efficiency of hydraulic valves by as much as 30%, as reported by the Hydraulic Institute, ultimately leading to a more reliable and productive hydraulic system.

In the realm of automotive engineering, the efficiency of hydraulic valves plays a crucial role in enhancing vehicle performance. Recent advancements in hydraulic system technology have resulted in significant boosts in productivity. For instance, an effective hydraulic valve can increase overall efficiency in vehicles by up to 30%, directly impacting fuel consumption and operational costs. With the global automotive hydraulic system market projected to reach USD 65.67 billion by 2033, growing at a CAGR of 5.9%, it's clear that the demand for efficient hydraulic solutions is on the rise.

Real-life examples illustrate the profound impact of hydraulic valve enhancements. Many automotive manufacturers have reported dramatic improvements in efficiency by integrating advanced hydraulic systems that incorporate AI for predictive maintenance and real-time performance monitoring. Additionally, optimizing the power coupling between electric and hydraulic systems in heavy-duty vehicles has led to greater stability and performance. By employing smarter technologies in hydraulic systems, manufacturers are not only reducing CO2 emissions but also cutting down energy consumption significantly, showcasing the pivotal role of hydraulic valve technology in shaping the future of sustainable automotive engineering.

Choosing the correct hydraulic valve can significantly enhance vehicle fuel efficiency. In the example shown, a vehicle's fuel efficiency improved from 15% to 20% after the optimization of the hydraulic valve system, resulting in an efficiency boost of 33.33%!