Leave Your Message

In the realm of lifting equipment, the performance and selection of valves play a critical role in ensuring safety and efficiency during operations. The Lifting Platform Hydraulic Valve is a pivotal component that directly affects the functionality of hydraulic systems utilized in various lifting platforms. As we approach 2025, understanding the advancements in hydraulic valve technology, along with the key factors influencing their performance, becomes increasingly vital for manufacturers and operators alike.

This insightful analysis aims to explore the latest trends and innovations surrounding Lifting Platform Hydraulic Valves, emphasizing the importance of selecting the right valve for specific applications. We will delve into the various types of hydraulic valves available, their operational principles, and how they contribute to the overall effectiveness of lifting platforms. By highlighting best practices for selection and maintenance, this resource intends to equip industry stakeholders with the knowledge needed to enhance safety and maximize productivity in lifting operations.

As the demand for more efficient and reliable lifting solutions continues to rise, the insights presented herein will serve as a guide for making informed decisions regarding Lifting Platform Hydraulic Valve performance and selection, ultimately fostering advancements within the industry.

When selecting hydraulic valves for lifting platforms, several key factors significantly influence their performance. Firstly, the type of hydraulic fluid used can affect the valve's response time and efficiency. Different fluids have varying viscosities, and selecting the appropriate fluid is crucial for optimal operation. Additionally, the temperature range in which the system will operate must be considered, as extreme temperatures can impact the fluid properties and, consequently, the valve's effectiveness.

Moreover, the design and material composition of the hydraulic valve play a vital role in performance. Valves constructed from robust materials can withstand higher pressures and offer greater durability, which is essential in lifting applications. It is also important to evaluate the valve’s flow rate and pressure ratings to ensure they align with the lifting platform's requirements. Compatibility between the hydraulic valve and other system components, such as actuators and pumps, is another critical consideration that contributes to overall system reliability and performance.

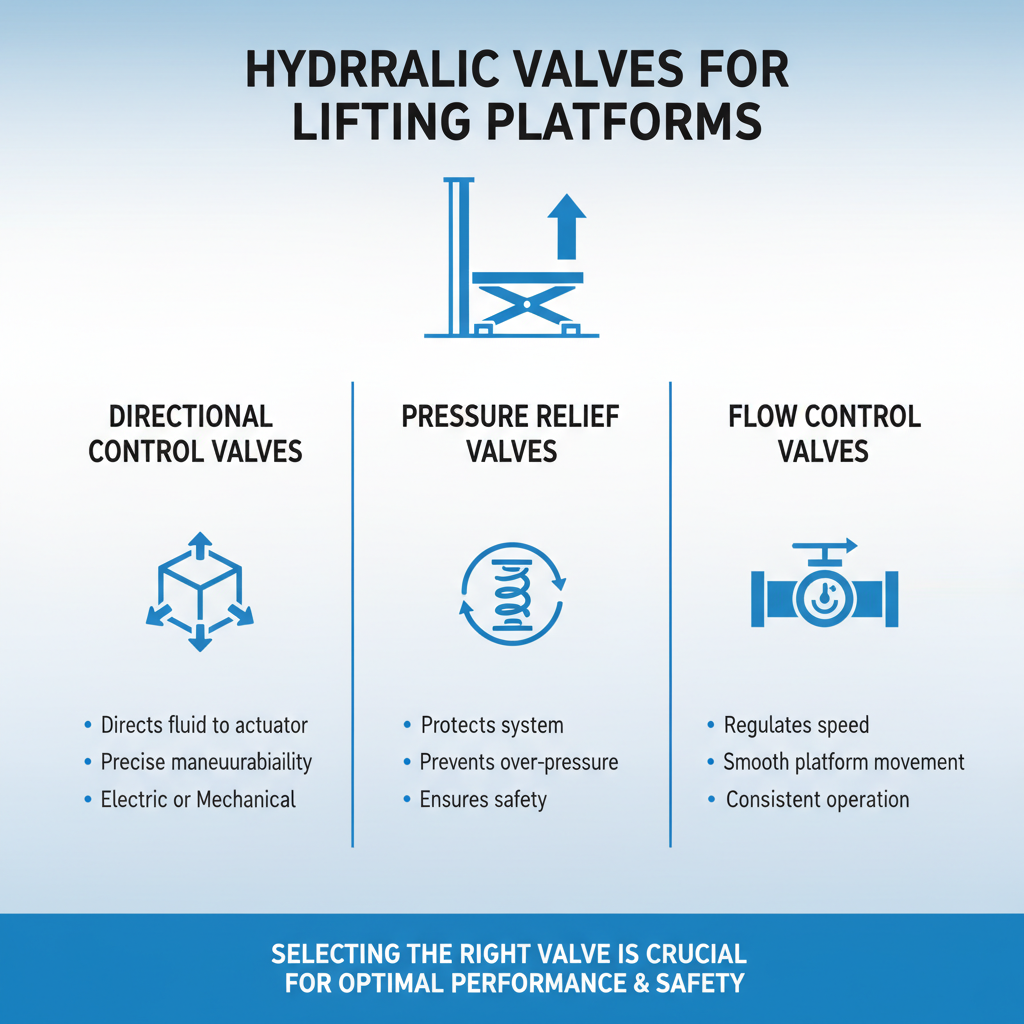

When selecting hydraulic valves for lifting platforms, it is essential to consider the various types that best suit specific operational requirements. The most common types include directional control valves, pressure relief valves, and flow control valves.

Directional control valves are crucial for directing the hydraulic fluid to the appropriate actuator, ensuring precise maneuverability of the lifting platform. These valves can be either electrically operated or mechanically actuated, providing flexibility based on the operational context.

Pressure relief valves are vital for safeguarding the hydraulic system against excessive pressure buildup. They ensure the system operates within safe parameters, preventing potential accidents and breakdowns. On the other hand, flow control valves allow for the regulation of fluid flow rates, enabling operators to adjust the speed of lifting or lowering actions as needed. By understanding these valve types and their functions, users can make informed decisions that enhance the efficiency and safety of their lifting platforms.

When selecting the right hydraulic valve for lifting platforms, several criteria should be prioritized to ensure optimal performance. First, pressure ratings are crucial as they determine the maximum pressure the valve can handle. It’s essential to match the valve's pressure specifications with the lifting platform's requirements to prevent failures. Additionally, flow rate capacity plays a significant role; a valve that cannot accommodate the necessary flow can hinder operations and efficiency.

Another vital consideration is the valve type, which should align with the specific application of the lifting platform. For instance, directional control valves, pressure relief valves, and flow control valves serve different functions, each impacting system operation. Moreover, materials and environmental compatibility are paramount, especially if the lifting platform operates in harsh conditions where exposure to corrosive substances is possible. Choosing a valve made from resilient materials can enhance durability and reduce maintenance costs, ultimately leading to improved performance and reliability of the hydraulic system.

Hydraulic valves are crucial components in lifting platform systems, ensuring efficient operation and safety. However, several common challenges can hinder their performance. One prevalent issue is leakage, which can occur due to wear and tear, improper installation, or insufficient maintenance. These leaks not only reduce system efficiency but also pose safety risks, making it essential for operators to regularly inspect and maintain their hydraulic systems.

Another challenge faced in hydraulic valve operation is responsiveness. Factors such as valve size, fluid viscosity, and temperature variations can lead to delayed response times, affecting the lifting platform's overall performance. To mitigate this, careful selection of valve specifications based on system requirements is vital. Implementing advanced control systems and utilizing high-quality components can enhance the responsiveness of hydraulic valves, ensuring smooth operations under varying conditions. Addressing these challenges effectively can lead to improved reliability and safety in lifting platform applications.

The future of hydraulic valves for lifting platforms is set against a backdrop of rapid technological advancements and an evolving market landscape. With an increasing global focus on efficiency and sustainability, hydraulic valve technology is likely to witness significant innovations. Emerging technologies, such as smart sensors and IoT integration, are reshaping the way hydraulic systems operate, enabling real-time monitoring and adjustments that enhance performance and reliability.

As the industry adapts to these changes, manufacturers are expected to prioritize the design and selection processes of hydraulic valves. Future trends indicate a shift towards more compact, high-performance valves that can support a variety of lifting applications with improved energy efficiency. The insights from trade shows and industry reports highlight the competitive dynamics among major players, reflecting a clear focus on incorporating advanced materials and cutting-edge designs to meet the changing demands of hydraulic applications in lifting platforms.